Responsibility is the intersection of sustainable choices with social and ethical practices.

To be a fully responsible apparel brand is a constant, complex challenge. We operate in an industry that too often defaults to the status quo and contributes to the production of over 100 billion pieces of apparel a year, along with 92 million tons of textile waste.

We are a small, independent company manufacturing limited-run collections. We are far from perfect, but we hold ourselves accountable to continually improve how we treat people, planet, and products to build a better company and industry.

Fabrics are critical; we are ambitious.

For us, to be Responsible regarding our product is not merely a factor of fabric composition or transitioning away from virgin plastics to recycled content. Making apparel that can be worn more, lasts longer, and needs to be replaced less often is just as important.

100% Certified

Since 2020 all of our primary fabrics have been certified by:

– bluesign

– OEKO-TEX

– RWS

PFC-free

Our water resistant coatings are free of harmful “forever chemicals” (PFAS) and use a more sustainable, water-based alternative that’s just as breathable and water-repellant.

Next steps: We’re working towards removing PFCs from our accessories and trims by the end of 2024.

75% Recycled Synthetics

Making gear with recycled fabrics allows us toreduce our carbon footprint and water use, and by the end of 2023 we will be using 100% recycled polyester.

Next steps: Transitioning our nylon program to use more recycled materials by 2024

Wear More, Wash Less

Two-thirds of a garment’s energy and water use comes at the hands of the consumer. We use fabrics and finishes with natural odor-resistant properties, like Merino wool, so you can wear more and wash less.

Our Future

We’re constantly looking to do better. Using manufacturing and dying processes that consume less water and less energy, exploring options for resale and repair, and making gear that’s in it for the long run.

Packaging

Our envelope mailers are made from 100% post-consumer recycled content, are biodegradable and are printed with water based ink. We have used these mailers since 2017, along with eliminating ‘folding paper’ and silica bags within our garment packaging in 2019 to reduce waste.

We print our hang tags on FSC-certified paper with soy ink printing and have eliminated the use of swift tags (also known as kimbles) or plastic pieces as much as possible, except certain accessories that require them for retail display. impresión

As of early 2022, we have moved away from individual polybags in our packaging, except for technical outerwear and sports bras that need the extra protection in transit. This has led to an 86% reduction in plastic in our packaging as we continue to seek out alternatives to move away from plastic packaging altogether. null

Manufacturing

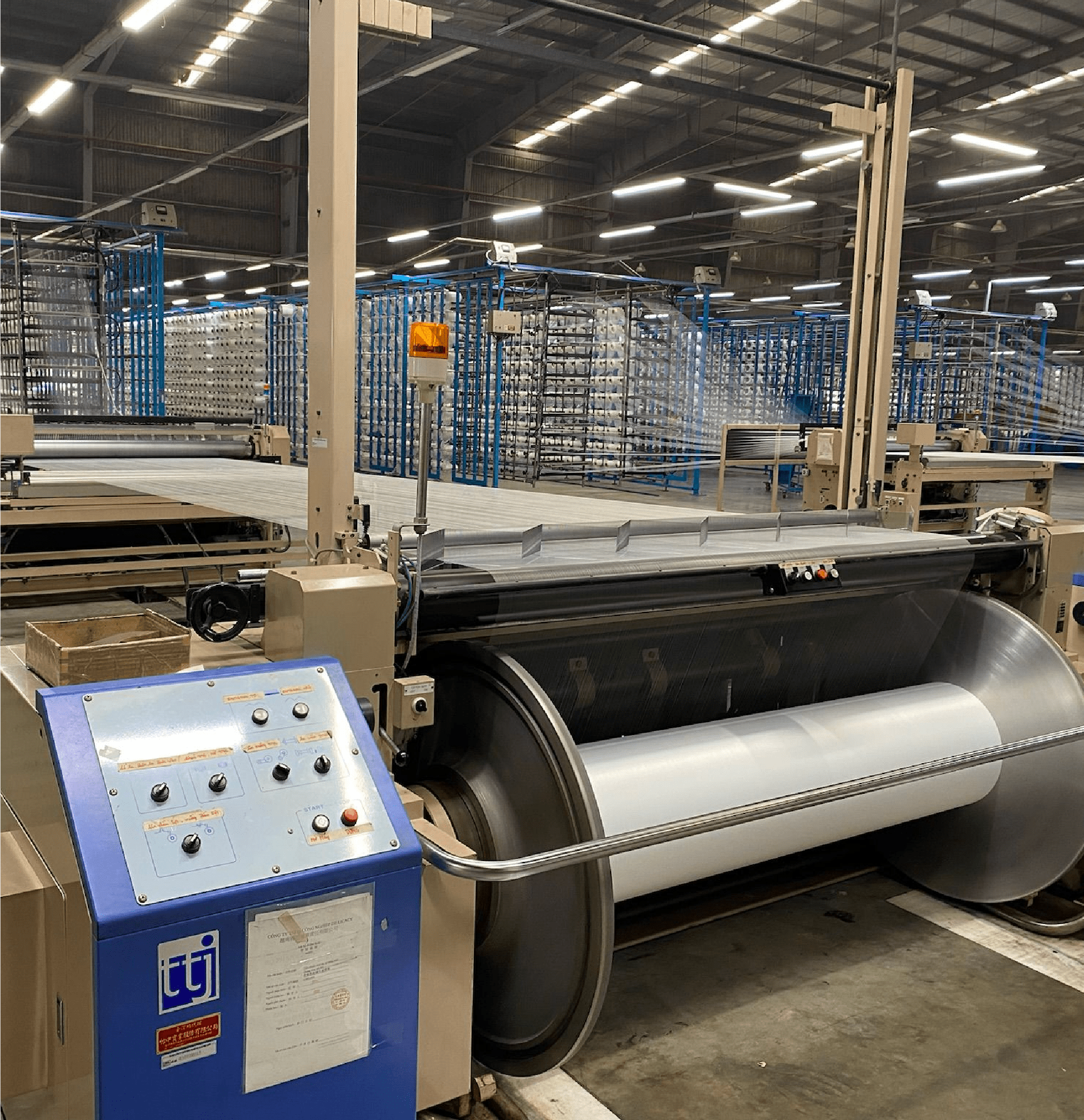

We are committed to working with manufacturing partners that have a proven track record of both ethical practices and technical ability.

The majority of Janji production happens across multiple factories in Vietnam, and our two primary partner facilities are voluntarily part of the WRAP certification process, receiving GOLD status to date. This standard, along with the premium we pay for our fabrics to be certified bluesign® from our mills, is a start.

For a deeper dive into our manufacturing standards, check out our Code of Conduct.

People

As a company founded on the social mission of improving access to and advocating for clean water as a basic human right, we are continually asking ourselves how we can do more around social inequality as we grow in outreach and scale.

We work with artists around the world to represent global creativity and support emerging artistic communities. In front of and behind the camera, we support local talent in the places we travel. Nonprofit water partners around the world help advance our mission of bringing clean water to all. null Black

Mission

Janji was founded with a mission: To expand access to clean water around the world.

Since 2012, we’ve given 2% of all proceeds to nonprofit partners worldwide. Since 2020, we’ve taken that mission to our own backyard: We give 100% of Janji Collective membership fees to U.S.-based nonprofits working to combat environmental injustice through water access for underserved communities.

We are committed to making more responsible choices

These initiatives are by no means all-encompassing, and stand as merely the beginning of what Janji is doing to measure, plan and reduce our impact along with transparently sharing that information with our community. This is an ever evolving dialogue in an ever changing landscape. Your feedback means the world to us — we would love to hear from you with ideas, comments or questions on any of these or other initiatives that you feel we should address.

Email us at hello@janji.com.